Core Facilities

Core Analytical Facility

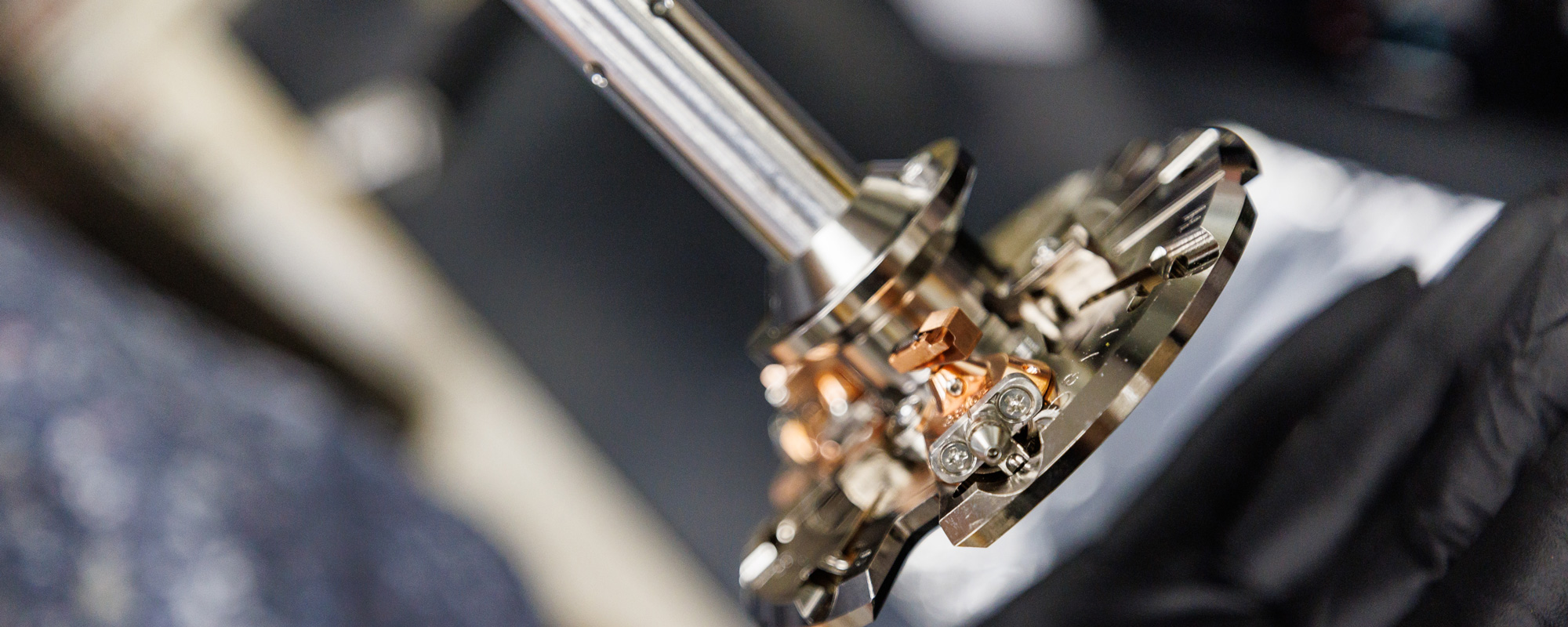

The Core Analytical Facility supports collaborative, multidisciplinary research involving instruments for electron, ion, and x-ray imaging, diffraction, and spectroscopy.

Powder Processing Facility

The Powder Processing Facility enables advances in novel metal alloy and ceramic compositions that are coupled with additive manufacturing.

Affiliated Facilities

The Alabama Atomization Facility provides solutions for producing metal powders by gas atomization. AAF’s capabilities also cover particle size measurement and sieving to produce a wide range of tailored particle sizes.

The Advanced Material Testing Laboratory in the South Engineering Research Center features multiple servo-hydraulic testing frames ranging in load capacity from 50 lbs to 250,000 lbs.

Instrumentation

The following instruments are available on The University of Alabama campus for materials research activities. Some of this equipment is in core facilities, research centers, or departments that offer hourly rate usage, while others are associated with collaborative facilities.